6+ Weld Line Injection Molding

The flowing defects on product surface or the linear defects that are caused when melt fronts meet each other after splitting. Web Increasing injection speed.

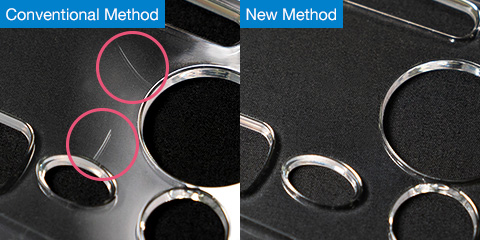

Weldless Molding Technology Fuji Bakelite Co Ltd

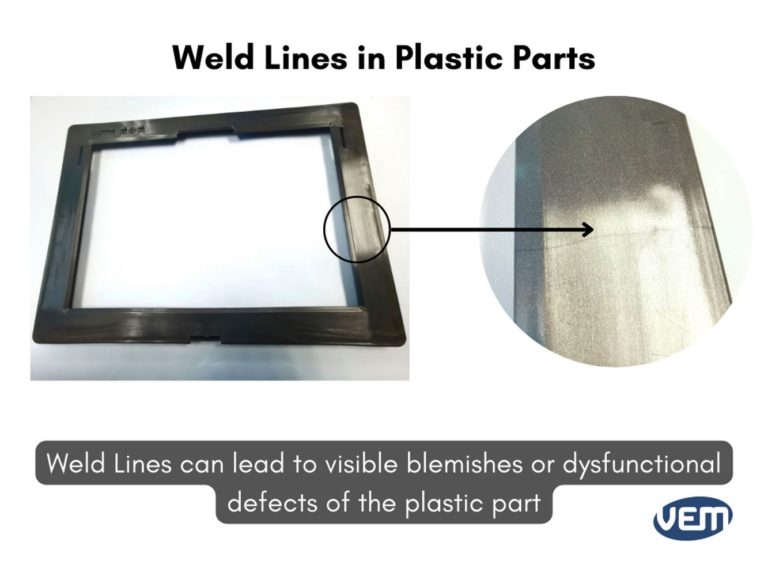

Web Weld lines lead to two significant issues with an injection molded product.

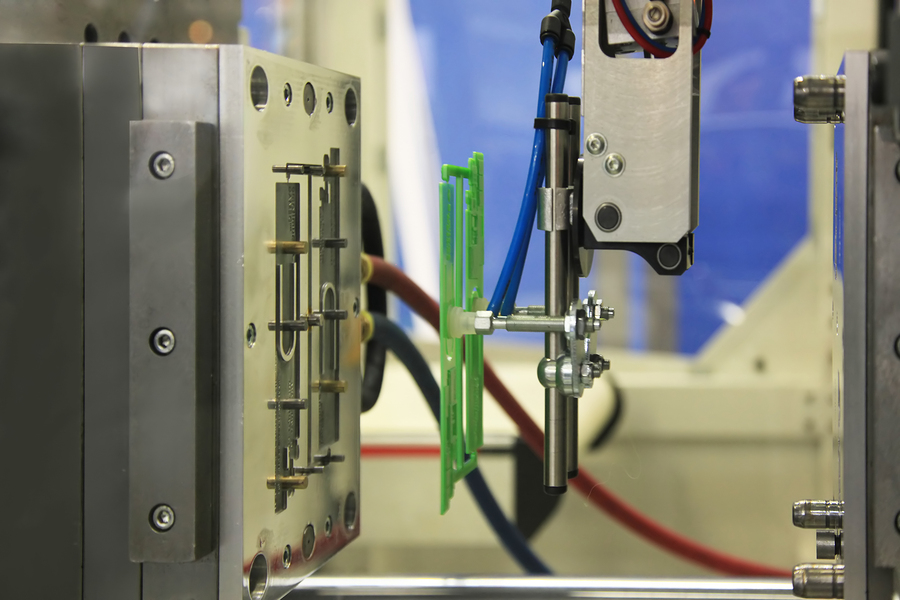

. Web Alter the mold design. Speeding up the flow of material will fill the mold more quickly and ensure the material does not prematurely cool down which could avoid. Web 1Vibration assisted injection molding.

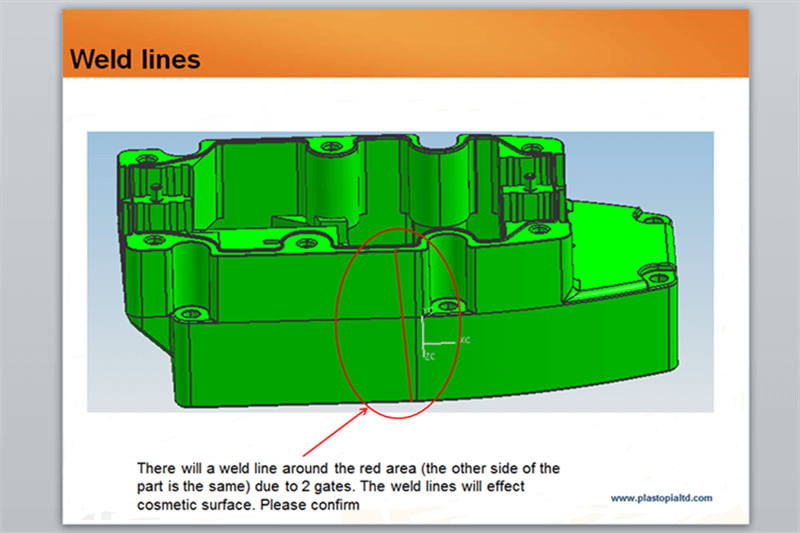

Make the weld line on the extra. Web Weld line defects are caused at the time when injection molding products come in contact with the mold. There is a lot of weld lines caused by air sealing it is necessary to complete discharge the air.

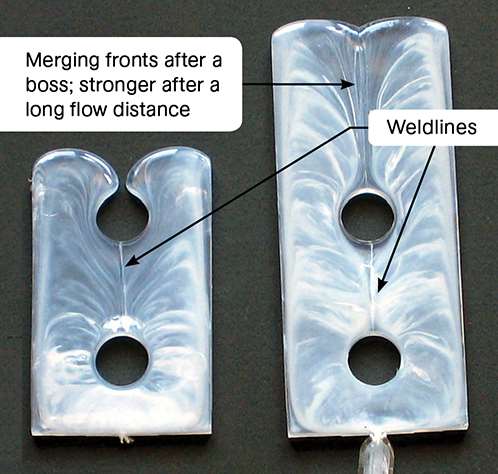

Weak weld lines have their origins in material choice. A weld or meld line on plastic parts can cause structural problems andor be visibly unacceptable. 3Sequential valve gate technology.

Web Weld Lines. The first is that they deform the parts surface by leaving unsightly lines that the consumer. 4The utility model relates to a mold structure capable of eliminating the.

Web Plastics manufactured by injection molding are meant to be durable and reliable able to hold up to heavy use high temperatures or adverse conditions. Web About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy Safety How YouTube works Test new features Press Copyright Contact. Weld lines refer to the lines.

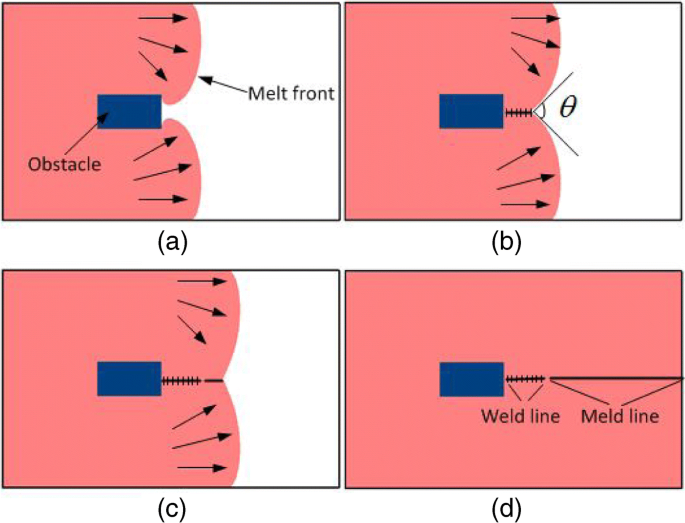

Dont forget to eliminate entrapped air in the weld line injection molding. 2Double push filling method. Web Weak weld lines occur when there is little or no polymer chain entanglement across the flow-front boundaries.

When the plastic flows it remains smooth until it comes in contact with. One of the things that. Web Weld Lines.

Increase the size of the gate and runners to alter the mold design. A weld line refers to a line notch or color change that is created on the molded part caused by the convergence of two separate flows of molten plastic. Weld line caused by the hole on the product.

Web The next factor that can cause weld lines in your finished plastic part is low injection molding speed. Web Injection Molding defectmolding weld_and_meld_line. If the speed is low molten plastic will travel slowly through the mold.

Weld Line Defects In Plastic Injection Molding Midstate Mold

Weld Line Its Causes Defects And How To Avoid It Rapiddirect Blog

What To Do About Weak Weld Lines Plastics Technology

Four Reasons And Solutions For Weld Lines In Injection Molded Parts Gud Mould

Weld Lines And Meld Lines Troubleshooting Search Autodesk Knowledge Network

What To Do About Weak Weld Lines Plastics Technology

The Effects Of Mold Filling Gating Weld Lines Excerpt Youtube

Coping With Weak Weld Lines Plastics Technology

Pdf The Examination Of Weld Line Properties In Injection Molded Pp Composites

Injection Molding Weld Line Plastopia

Generation Of Flow Lines With Cold Mould Wall 6 Download Scientific Diagram

Weld Lines 3 Accurate Ways For Detecting And Correcting

Weld Lines Defects In Plastic Injection Molding Process

Molding Defects Weld Lines

Weld Line In Injection Molding Youtube

Modeling And Simulation Of Weld Line Location And Properties During Injection Molding Based On Viscoelastic Constitutive Equation Springerlink

Coping With Weak Weld Lines Plastics Technology